Ore Mill Calculation Working Process Of Crushers

Primary Crusher Optimisation for Improved

5 天之前 — crushers take blasted, runofmine, or runofquarry feed up to 1500 mm and produce a product ranging in size from 300 mm for conveyor transport, or 200 mm for SAG mill feed The primary can produce these sizes at a rate of 150 to 12 000 mtph 2020年12月1日 — Crushing behaviour in a VSI involves multiple mechanisms of impact breakage Abstract Particle scale modelling of comminution processes can provide Advanced comminution modelling: Part 1 – Crushers☆4 天之前 — carried out by size reduction performed by crushers and grinding mills The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals LECTURE NOTES KIIT Polytechnic2016年2月10日 — The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require Design of a crushing system that improves the crushing

.jpg)

Crushing and Screening Handbook AusIMM

2021年6月24日 — TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process 2021年12月15日 — In order to assign mill performance to the loading point, the ore should be traced from the production face to the mill or, equivalently, the material in the mill at a given point in time should be traced back to Crusher to Mill Transportation Time 2023年5月16日 — The improvement of technological and crushing processes in particular is closely related to modeling Simulation allows studying the laws of the crushing process to improve the calculation methods of Modeling and Improving the Efficiency of This work provides the Bond ball mill work index, which expresses the resistance of material to ball milling Table 2 lists a number of physicmechanical properties of ores used in the facility For each ore type, the (PDF) Field monitoring and performance

.jpg)

Ore Crushing SpringerLink

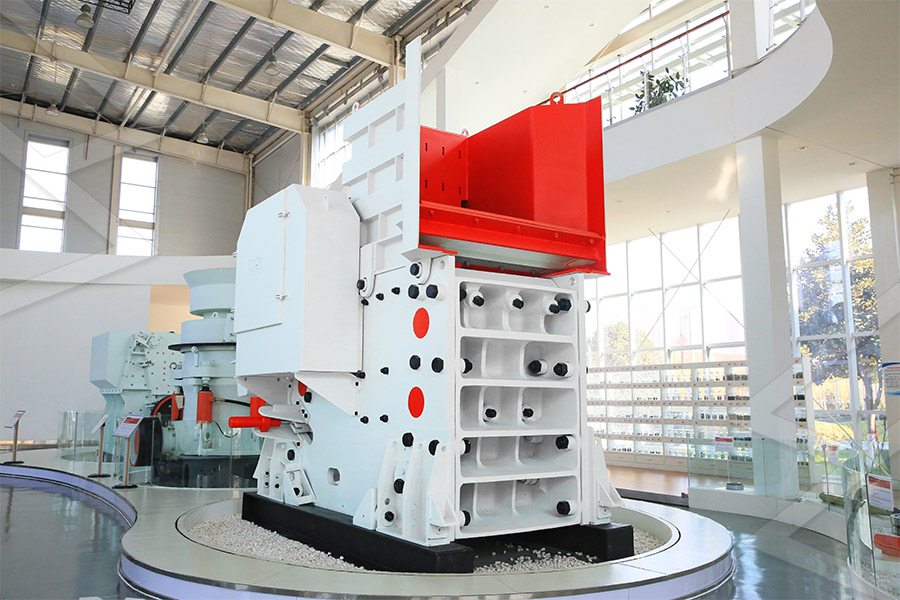

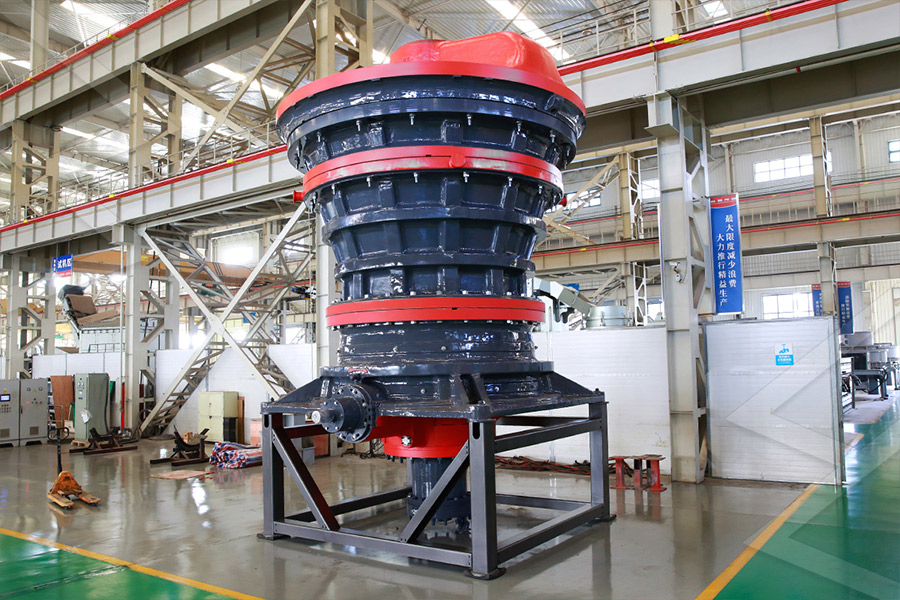

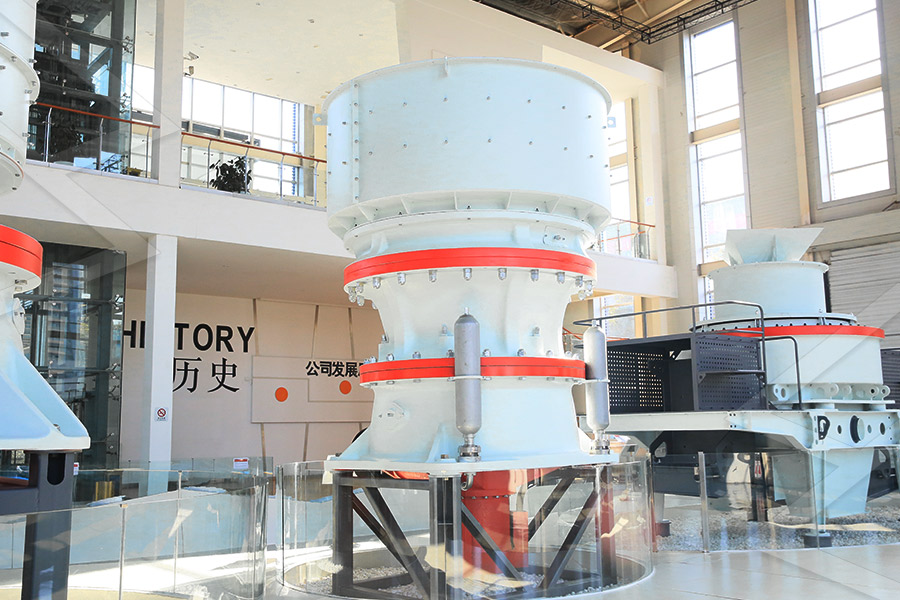

2023年7月22日 — The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a 2024年3月19日 — Houses the crushing process: Consists of the bowl liner (fixed outer cone) and mantle (moving inner cone); determines the size reduction ratio and overall performance Example Analysis: Working Cone Crusher Diagram: Simplified Guide JXSC2015年6月16日 — Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper According to Bond’s Third Theory of Bond Impact Crushing Work Index Procedure Hammer mills and impact crushers One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers Hammer mill crushers use continuous hammer blows to Types of Crushers: What You Need to Know

.jpg)

Understanding Industrial Crushers: Types And Applications

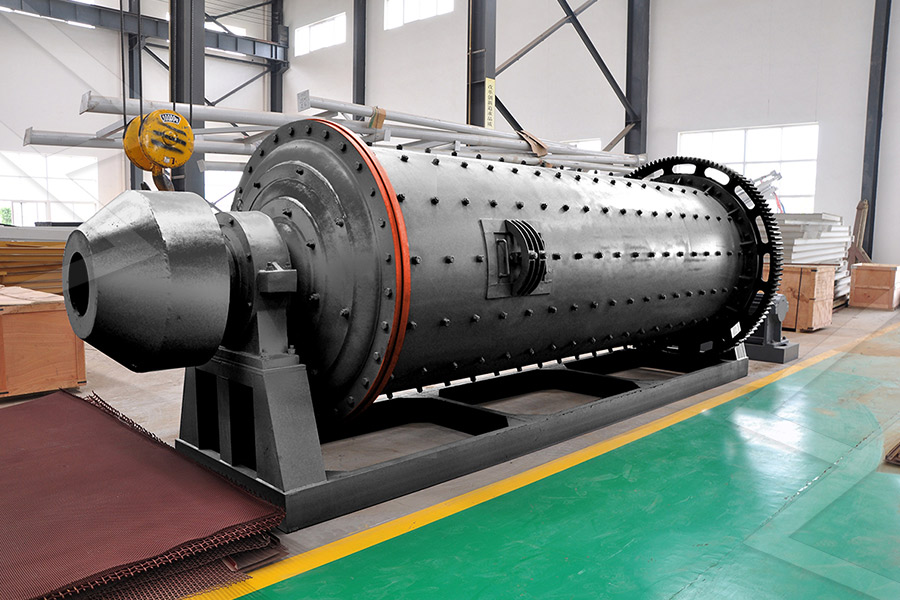

2023年8月1日 — Impact crushers; Impact crushers earn their name from the impactful way they crush materials These machines can grind large pieces of rock, ore, concrete, or other materials, preparing them for further processing in a ball mill or hammer mill5 天之前 — the reduction in size of the ore The crushing plant can be provided with almost any type of primary rock crusher The rock/ore determines the type of crusher The plant capacity determines the size of the crusher As the term ‘primary’ implies, these crushers are used in the first stage on any size reduction cyclePrimary Crusher Optimisation for Improved This step involves the material being retained inside the mill for a specific time (with or without grinding balls) which is calculated by applying Bond’s work index to the process calculation This index takes into account the material ore hardness and feed size, mill speed, material recirculation, desired fineness, etcThe six main steps of iron ore processing Multotec2021年6月24日 — TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Crushing and Screening Handbook AusIMM

.jpg)

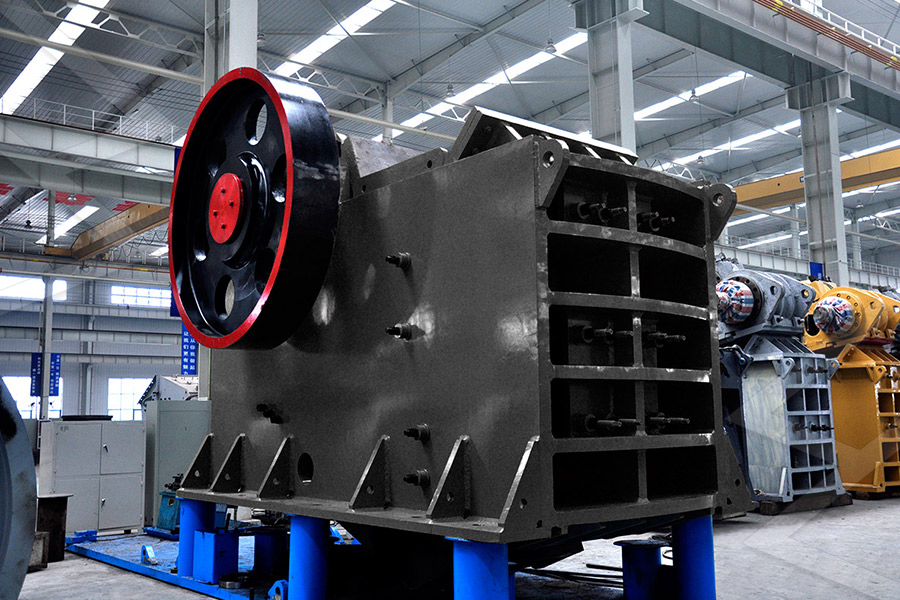

Jaw Crusher Working Principle 911Metallurgist

2021年5月6日 — The broken ore then falls through the crusher to be taken away by a conveyor that is under the crusher Although the jaws do the work, the real heart of this crusher is the TOGGLE PLATES, the PITMAN, and the PLY WHEEL Forced Feed Jaw Crushers These jaw crushers are ideal for small properties and they are of the high 2015年4月16日 — For example, in 1915, at the huge Homestake operation, there were no less than 20 Gates’ small gyratory crushers sizes No 5 and 6 to prepare the ore for the batteries of >2500 stamp mills Rock Crushers for Sale Most commercial crushed stone plants were small, and demand for small product sizes practically nonexistentRock Crusher History 911MetallurgistJaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always)Cone Crushers (Parts of a Cone Crusher) Explained saVRee2023年2月28日 — Roll crushers are machines used to reduce the size of materials by compressing them between two rotating rollers They are commonly used in the mining and construction industries to process Understanding the Different Types of Crushers:

.jpg)

A review of modeling and control strategies for cone crushers

2021年8月15日 — Several works from the literature have reported applications of process control strategies in the mineral processing industry For example, Wei and Craig (2009) published a survey with qualitative data from process control solutions, and Bouffard (2015) reported quantitative data supporting the benefits of such strategies A series of works 2016年3月11日 — The feed for Gyradisc crushers usually has a topsize not larger than 75MM (3 In) for the larger units and 30MM (1¼ In) for the smaller size crushers Gyradisc crushers differ from conventional conetype crushers because the comminution of material is achieved by a reduction process called InterParticle ComminutionCrushing Plant Flowsheet DesignLayout 911Metallurgist2015年7月29日 — The single most common reason for an increase or drop in the production of fines is the WORK INDEX of the ore If you remember, the work index of the ore is a method of measuring the degree of hardness As the ore becomes harder the fracture lines in the rock become cleaner or sharper with less crumbling of the face and edges of the Ore Feed Size * Work Index Hardness: Crushing Mill TonnageFault diagnosis of mechanical equipment in high energy consumption industries in China: A review Yongjian Sun, Xiaohong Wang, in Mechanical Systems and Signal Processing, 2023 211 Crusher Crusher is a widely used gravel machine, which is mainly used in the crushing of granite, limestone, quartz and other stones The crusher can crush the stone Crusher an overview ScienceDirect Topics

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 — Jaw crusher needs to work together with feeding equipment to complement the crushing process You can see that the granite material is reduced by the compressive force generated by two jaw dies When the size of the material is smaller than that of discharging port, the final product will fall out of the bottom and be sent by the conveyor 2015年6月23日 — Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the Types of Crushers 911MetallurgistThe Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feedCone crusher basics in 4 minutes SRP2023年2月21日 — Working Principles of Jaw Crushers Jaw crushers are used to crush and reduce the size of various materials, including rock and ore They work by using compressive force to break down the materials Understanding the working principles of jaw crushers is important for ensuring that you choose the right crusher for your specific needsThe Ultimate Guide to Jaw Crushing Machines: Types

HPGR 911Metallurgist

2016年7月14日 — A Cerro Verde expansion used a similar flowsheet as the 2006commissioned circuit to triple circuit capacity The expansion circuit includes eight MP1250 cone crushers, eight HPGRs (also 24 x 17m units, with 5 MW each), and six ball mills (22 MW each), for installed comminution power of 180 MW and a nameplate capacity of 2024年3月1日 — The energy consumption for crushing an ore is a function of its hardness, feed sizes and product sizes The standard measure of energy demand is Bond work index The work index, w i, represents the kilowatt hours per tonne required to reduce the material from theoretically infinite feed size to 80Design, Fabrication and Testing of a Double Roll Crusher2013年5月5日 — design of crushing plant steve mellor pdf – Rocks Process KWS aggregate processing plant design calculation Steve Mellor explains why uses aggregate risk as a tool for managing the risk Before starting a QRA on a Aggregate Processing Plant Design Calculation Crusher Mills2015年12月26日 — Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput; F80 Top 2,000 to" h="ID=SERP,51792">Crushing in Mineral Processing 911Metallurgist

SAG Mill Grinding Circuit Design 911Metallurgist

2016年6月6日 — Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughput The effect of feed size is marked, with both larger and finer feed sizes 2021年1月12日 — crushers: two are semimobile in the Valley pit and one is permanently located to process ore from the Lornex pit As the Valley ore comprises the bulk of our feed and is generally much harder than the Lornex ore, the two semimobile crushers (Crusher 4 and Crusher 5) have been fitted with WipFrag cameras and will be the subject of the The Importance of Primary Crushing in Mill Feed Size 2022年1月14日 — Jaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa Working Principle Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a Working Principle of 4 Commonly Used Crushers2020年12月17日 — The backbone of all these analyses is careful calculation that takes into account the capabilities and constraints of different crushers and operational requirements In these cases, also cone crushers can carry out the first stage of the crushing process The cone crushers are equipped with a hydraulic setting adjustment system, which Crushing 101 – Different types of crushers for distinctive needs

.jpg)

The Influence of the Structure of Double Toothed Roller Crusher on

2018年11月7日 — Because the grinding process of cereal feed is very complex, it is difficult to measure the relevant parameters directly by sensors (Tian et al, 2019;Mugabi et al, 2017)2024年9月24日 — Celculaled camel ty16 ' 25 7 I n 0 05 1 15 2 25 Actual capacl tylh' Q Present Eqn + Rose 8 Engllsh Eqn Fig 1 Comparison of calculated capacltles wlth the oata of Hersam (1 9231 for different machlne parameters thereby influencing the degree of compaction of the product The final equation for the capacity of jaw crushers canCapacities and performance characteristics of jaw crushersThe process of reducing mined ore for processing is known as ‘comminution’, which is defined as ‘the action of reducing a material, especially a mineral ore, to minute particles or fragments’; this is normally achieved at mining operations through one or more stages of crushing and milling Early mining activities were labour intensive Ore breakdown Gyratory Crusher (Gyratory Crushers Explained) saVRee2021年9月15日 — Crusher eccentric shaft rotation has a large impact on productivity The rotation of various crushers should be within a certain range, otherwise, too high and too low rotation will reduce productivity 8 Factors That Affect Production Efficiency of

.jpg)

Capacity Calculations of the Crasher with Stops on a Roll

2022年8月21日 — Abstract All the enterprises of metallurgical industry produce and use crushed materials obtained by crushing The share of produced energy spent on crushing is more than 5% in the global energy balance In this paper, we consider the schematics of a crushing machine with stops on the roll, the design of which forms a complex stress state 2018年4月5日 — EF5 Fine Grinding in ball mills to product sizes finer than 80% passing 200 mesh (75 micrometers) EF6 High or low ratio of reduction rod milling EF7 Low Ratio of reduction ball milling EF8 Rod Milling Rod Mill Design Calculations 911Metallurgist2023年2月23日 — A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance Whether Understanding the Cone Crusher Working Principle: How It2019年3月21日 — The crushing of minerals and ore is of great industrial importance With global population growth, urbanization, and continuing improvements in living conditions, the productivity and efficiency of existing crushers must be increased to meet the growing demand []Cone crushers are characterized by a continuous operating cycle and may Forces in a Cone Crusher Steel in Translation Springer

.jpg)

Understanding Types of Jaw Crusher: A Comprehensive

These hefty machines kick off the process that turns plain raw stuff into the polished materials that are key for all sorts of building and crafting jobs If it weren’t for the strong crushing power of jaw crushers, getting minerals out of ore would be way more of a hassle, really showing just how crucial they are to the whole industryAG/SAG mill is inefficient in grinding particles of a certain size, typically in the range of 2555 mm, ie, pebbles Therefore, cone crushers are often used as pebble crushers and integrated into AG/SAG mill circuits to break the critical size particles that accumulate in the mill and to increase the performance of the primary grinding circuitsDynamic Modeling and Simulation of SAG Mill Circuits 2016年2月18日 — From AllisChalmers’ Superior Primary and Secondary Crushers ° Actual required depends on stone hardness, reduction ratio, and so on If a 60in gyratory crusher is to process material from a quarry where a shovel loads the raw material, the shovel would probably have to have a dipper capacity of at least 5 cu yd to be compatibleEstimate Jaw Crusher Capacity 911MetallurgistAbstract: There are few studies concerning the process simulation of vertical roller mills (VRMs) In this research work, the application of population balance model for simulation of a VRM in a cement clinker grinding circuit was investigated The residence time distribution (RTD) was measured, andModeling and simulation of vertical roller mill using

.jpg)

Ore Crushing SpringerLink

2023年7月22日 — The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three2024年3月19日 — Houses the crushing process: Consists of the bowl liner (fixed outer cone) and mantle (moving inner cone); determines the size reduction ratio and overall performance Example Analysis: Working Cone Crusher Diagram: Simplified Guide JXSC2015年6月16日 — Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper According to Bond’s Third Theory of Bond Impact Crushing Work Index Procedure Hammer mills and impact crushers One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers Hammer mill crushers use continuous hammer blows to Types of Crushers: What You Need to Know

.jpg)

Understanding Industrial Crushers: Types And Applications

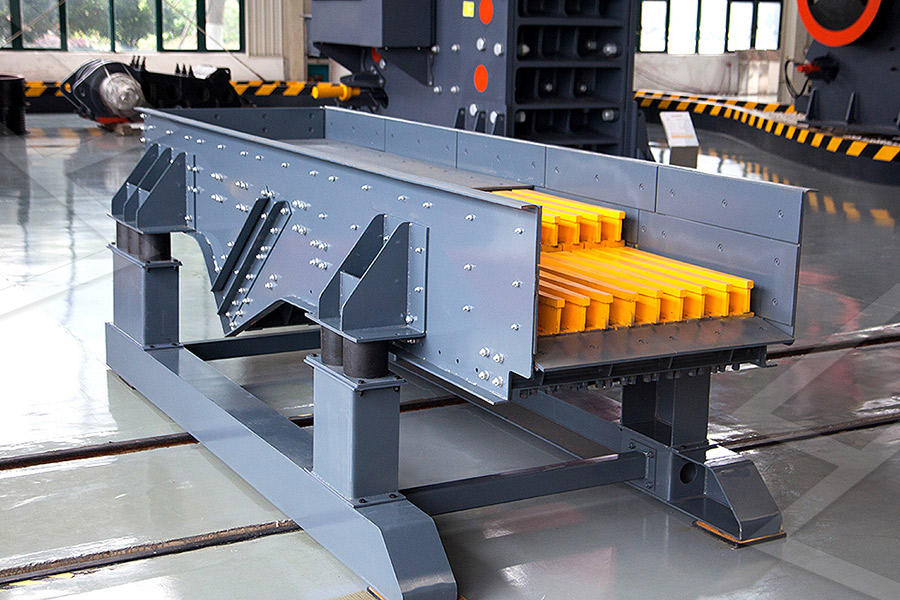

2023年8月1日 — Impact crushers; Impact crushers earn their name from the impactful way they crush materials These machines can grind large pieces of rock, ore, concrete, or other materials, preparing them for further processing in a ball mill or hammer mill5 天之前 — the reduction in size of the ore The crushing plant can be provided with almost any type of primary rock crusher The rock/ore determines the type of crusher The plant capacity determines the size of the crusher As the term ‘primary’ implies, these crushers are used in the first stage on any size reduction cyclePrimary Crusher Optimisation for Improved This step involves the material being retained inside the mill for a specific time (with or without grinding balls) which is calculated by applying Bond’s work index to the process calculation This index takes into account the material ore hardness and feed size, mill speed, material recirculation, desired fineness, etcThe six main steps of iron ore processing Multotec2021年6月24日 — TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Crushing and Screening Handbook AusIMM

Jaw Crusher Working Principle 911Metallurgist

2021年5月6日 — The broken ore then falls through the crusher to be taken away by a conveyor that is under the crusher Although the jaws do the work, the real heart of this crusher is the TOGGLE PLATES, the PITMAN, and the PLY WHEEL Forced Feed Jaw Crushers These jaw crushers are ideal for small properties and they are of the high 2015年4月16日 — For example, in 1915, at the huge Homestake operation, there were no less than 20 Gates’ small gyratory crushers sizes No 5 and 6 to prepare the ore for the batteries of >2500 stamp mills Rock Crushers for Sale Most commercial crushed stone plants were small, and demand for small product sizes practically nonexistentRock Crusher History 911MetallurgistJaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always)Cone Crushers (Parts of a Cone Crusher) Explained saVRee