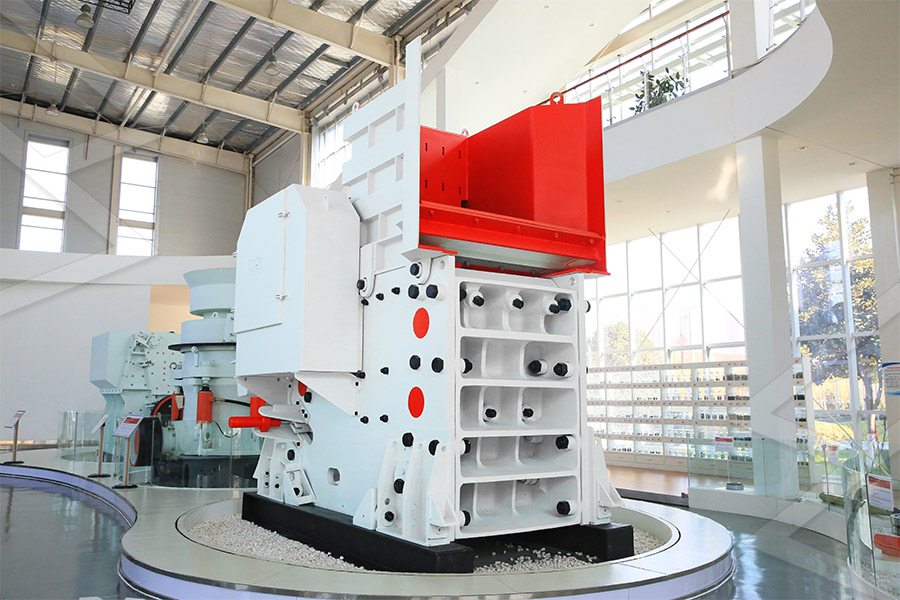

High Efficient Quartz Spiral Chute Mineral Processing

.jpg)

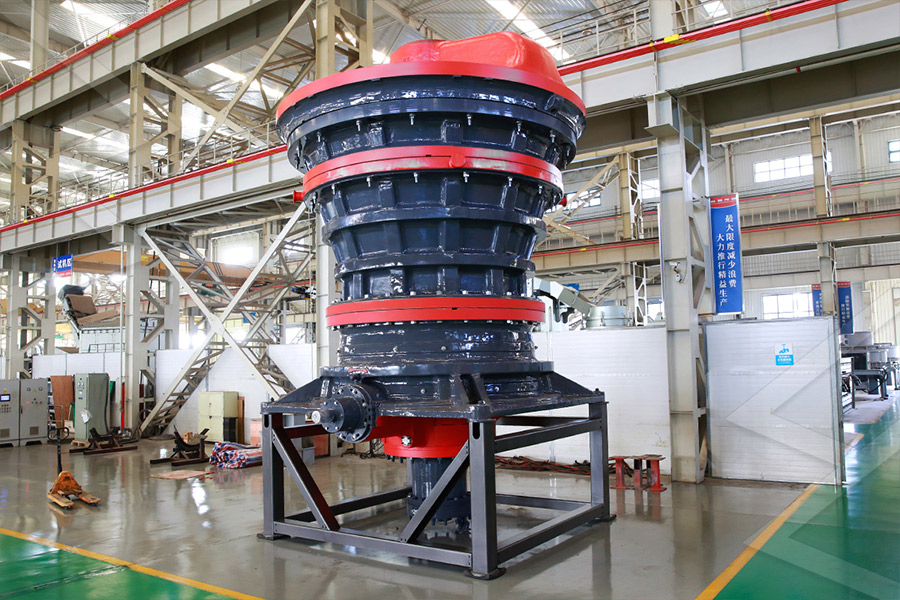

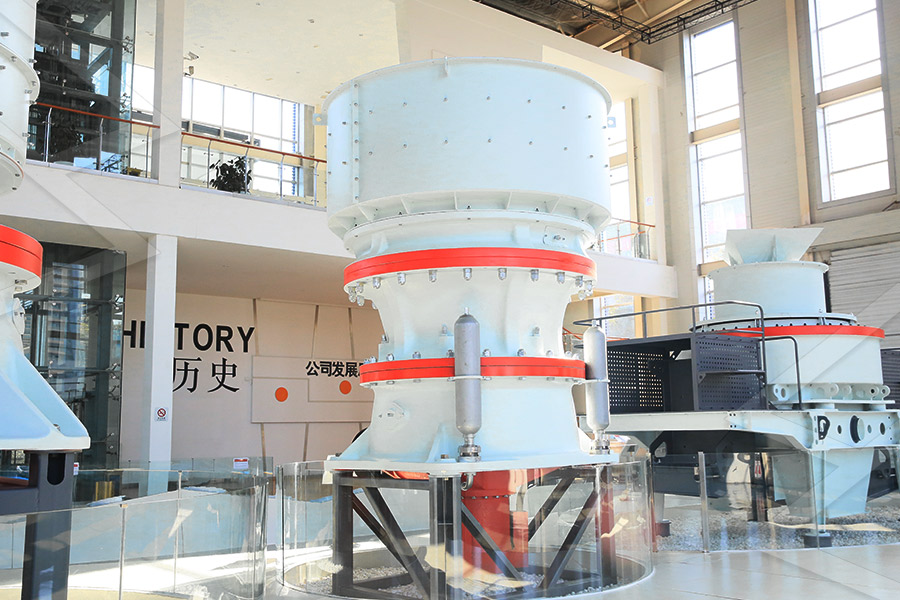

Improving Mineral Processing Efficiency With

2024年9月24日 — Using gravity and centrifugal force, the spiral chute effectively separates the copper ore from the gangue minerals, resulting in an efficient and costeffective extraction process In copper processing, 2021年3月8日 — The SC25 spiral has shown better Cr2O3 separation efficiencies than the SC21 model and with higher SiO2 rejection at saleable grades, thus providing an Evaluating separation efficiencies of Multotec’s new 2021年3月8日 — use of spiral separation technology to treat fine material (80% passing 75 μm), has historically been ineffective at this size range A fine spiral separator may Spiral conditions for the recovery of ultrafine particles2020年5月6日 — The Spiral concentrator has performed better at feed pulp density of 30% by producing concentrate of high grade (935%) and with highest recoveries of 96% The Effect of Operating Parameters on the Performance of

10 QA You Need To Know About Spiral Chute

2021年6月30日 — The spiral chute is widely used to separate nonferrous metals, ferrous metals, nonmetallic minerals, rare metal minerals and heavy minerals in tailings with a particle size range of 03002 mm, such as The trajectories of the mineral particles with different particle sizes and specific gravities were modeled results show that the smalldiameter spiral chute with a constant pitch to Influence of main structural parameters of spiral chute 2024年6月7日 — The spiral chute plays an important role in the mineral mining and ore dressing industries as an efficient and practical gravity ore dressing equipment With Dasen Mining’s spiral chute equipment and Beyond Jigs: Advantages of Spiral Chutes in Fine 2023年8月7日 — Key Benefits of Using Rotary Spiral Chutes Enhanced Recovery Rates: The spiral motion and centrifugal force maximize the separation of heavy minerals, resulting in higher yields Efficient How Rotary Spiral Chutes Optimize Mineral

Mining Spiralling in control ScienceDirect

2006年3月1日 — A spiral will normally achieve a minimum 3:1 upgrading ratio (ratio between head feed grade of heavy minerals and concentrate grade) Therefore, as with most Large mineral processing plants consist of thousands of spiral concentrators resulting in large plant footprints (capital intensive) and the adjustment of splitters is time consuming, Case study: High capacity spiral concentrators SciELO2024年6月7日 — The spiral chute plays an important role in the mineral mining and ore dressing industries as an efficient and practical gravity ore dressing equipment With Dasen Mining’s spiral chute equipment and Beyond Jigs: Advantages of Spiral Chutes in Fine 2020年11月13日 — While using the spiral chute to remove the heavy minerals in the quartz sand, it can also remove part of the flake mica minerals Equipment Needed: Spiral chute (4) Flotation Method If there Quartz Impurities Removal Process and

How to Increase the Efficiency of Spiral Chute?

2023年10月5日 — To increase the efficiency of a spiral chute, you can focus on several key aspects Here are five points to summarize the process: 1 Optimize Design and Geometry: — Ensure the spiral chute has 2021年3月8日 — IMPC 2020: XXX International Mineral Processing Congress, Cape Town, South Africa, 1822 October 2020 5 Separation efficiency on a spiral Yield, grade and recovery are the main separation attributes used to measure the performance of a spiral This paper uses the mentioned attributes in addition to the HollardBatt equation to calculateEvaluating separation efficiencies of Multotec’s new 2024年9月29日 — The output of the magnetic separator is sent to the spiral chute by a slurry pump Through gravity separation method to remove light minerals The spiral chute gravity separation plant has two stages: the middling from the first stage spiral chute plant goes to the second stage spiral chute for reprocessingRutile Processing Beneficiation JXSC MineralOur range of spiral concentrators Multotec Australia offers a wide range of spiral concentrators that can be found at our branches in Brisbane, Mackay, Perth, Newcastle, Newman and Emerald, Our range of spiral concentrators is designed for use in the mineral processing of chrome, coal, iron ore, gold, nickel and zinc The video below gives Spirals in Australia mineral processing Multotec

.jpg)

Gold Processing Equipment, Process Flow, Cases JXSC Machine

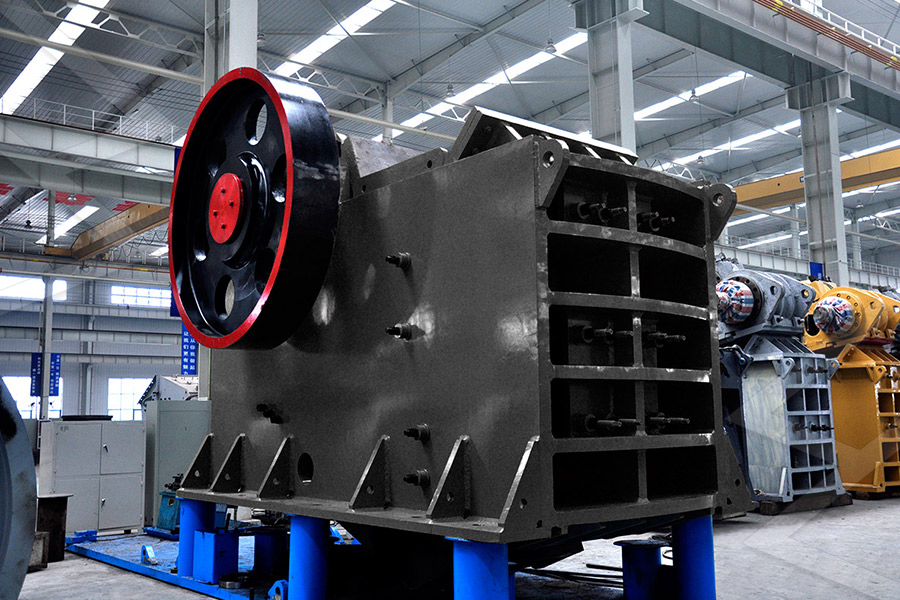

2019年8月22日 — Gravity beneficiation is refers to separating gold ore according to mineral density and plays an important role in contemporary mineral processing methods The main gravity separator equipment are chute, shaker table, mineral jig, hydrocyclones, etc Gold flotation Flotation process is widely used for lode gold processing2024年9月29日 — Ilmenite gravity separation The gravity separation method is suitable for processing coarsegrained and finegrained aggregate disseminated ilmenite After crushing, the raw ilmenite ore is separated and discarded by gravity separation equipment, such as the shaking table, spiral chute, etcA large number of gangue minerals and slime are Ilmenite (Titanium) Mining Process JXSC Mineral2024年9月29日 — The working principle of the spiral chute is as follows: 1 The sand pump sends the ore to the two feed inlets at the upper end of the screw, adding supplemental water to adjust the concentration of the ore pulp; 2 The ore pulp naturally swirls from high to downward, generating a kind of inertial centrifugal force in the rotating slope; 3 As the Spiral Chute with High Quality Fote Machinery2024年9月29日 — The spiral separator is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table, and centrifugal concentrator Sprial Chute Working Principle Raise the spiral chute and fix it in the proper position, sand pump send the ore to the feed inlet, adding water to adjust Spiral Chute JXSC Mineral

.jpg)

(BLL) Spiral Chute miningmachinerys

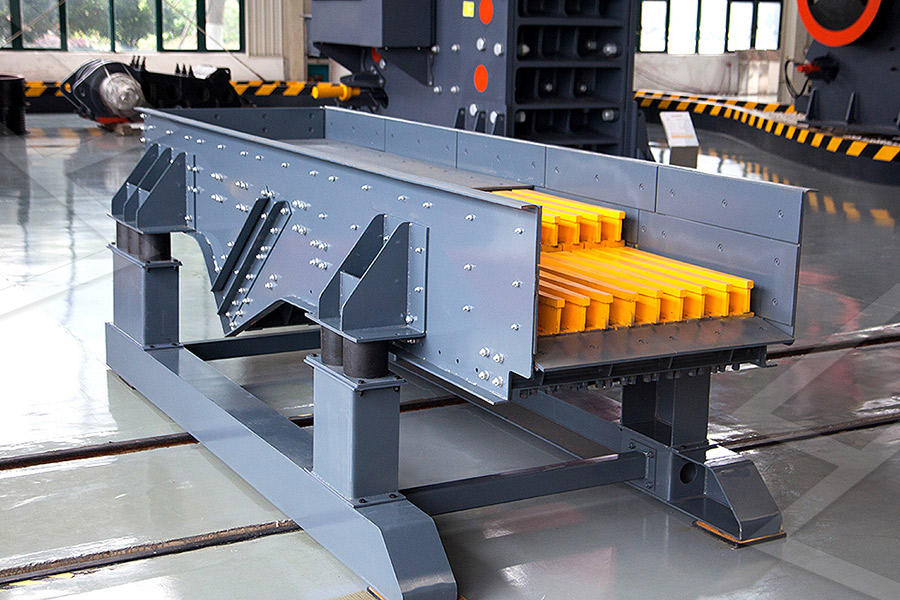

The spiral chute is mainly composed of feed chute, flushing aqueduct, flange, tailings chute and centralized pipe Spiral chute used in concentrator Working Principle The uniform slurry is slowly fed to the surface of the spiral groove through the feeding trough installed at the head end of the spiral groove for sorting4 天之前 — Copper ore beneficiation usually adopts gravity separation, flotation, magnetic separation, leaching and other methods JXSC supports customized copper processing plant and equipment, fully suitable for Copper Processing Plant, Equipment JXSC 4 天之前 — The spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals Because of its simple Spiral Separator Beach Sand Spiral Chute JXSC 2023年10月1日 — Gravity separation is one of the commonly used beneficiation methods for gold ore According to different mineral processing equipment, the gold ore gravity separation process can be divided into jig mineral processing, shaking table mineral processing, chute mineral processing and spiral chute processing Different mineral 4 Kinds of Gold Ore Gravity Separation Equipment and

Xinhai Mining Silica Sand Processing Equipment Process and

Spiral Chute More Details After mineral processing and purification, it can become highpurity and ultrahighpurity quartz sand At this time, the material can be widely used in hightech fields such as aerospace, atomic energy technology, laser, optical cable communication, and military industry reverse flotation process is often High Efficiency Agitator Washer, Spiral Chute Washer The blade, shaft and tank of highefficiency agitator washer are lined with Xinhai wearresistant rubber, which is easy to resist the material impact and abrasion, has long service life and low failure rate Mineral Processing EPC and Equipment Tel: +33High Efficiency Agitator Washer, Spiral Chute Washer Xinhai2024年5月30日 — A spiral chute separator is a gravity concentration device used primarily in the mineral processing industry to separate particles based on their specific gravity Here’s how it works: Working Principle: Feed Preparation: The material to be processed (usually in slurry form) is fed into the top of the spiral chuteWhy Spiral Concentrators Are Used for concentrated low grade mineral The mineral dressing spiral chute is a scientific and technological product developed by our company through years of mineral processing experience It is the best equipment for mining and mineral processing, especially for placer mining on seashores, riversides, sand beaches, and streams high recovery rate, large processing capacity, and Spiral Chutes JXSC

Jaw Crusher Manufacturer, Ball Mill, Shaking Table Supplier

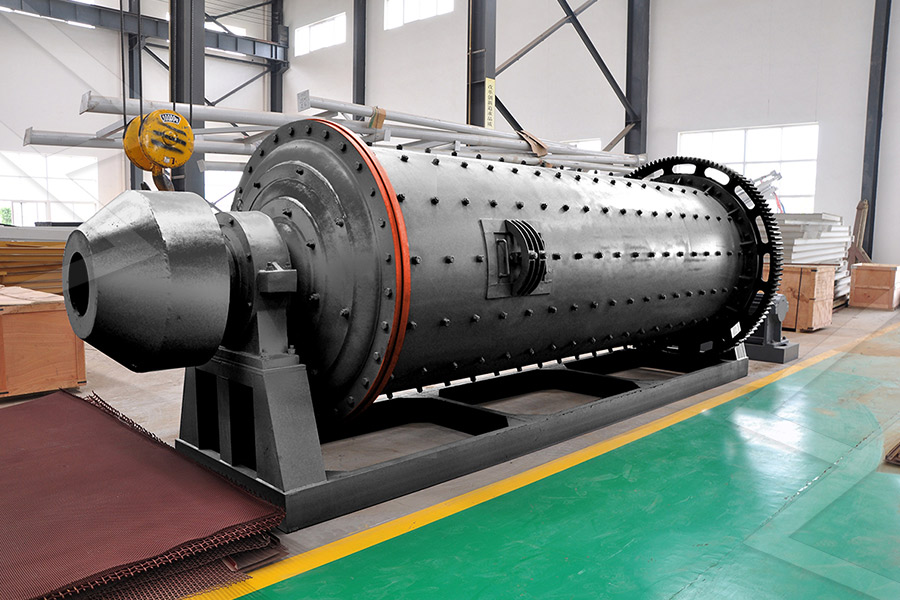

High Efficiency China Stone Grinder Machine Gold Mining Equipment Gold Processing Grinding Ball Mill FOB Price Gold Ore Processing Plant, Crushing Quartz Hardrock Gold Gold Mining Equipment FOB Price: US $1,25019,000 / Set Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputation 2024年9月29日 — The diaphragm jig separator machine has high beneficiation efficiency and can process coarse particle ore, separate tungsten, tin, and the like with a particle size of up to 16 mm and a minimum particle size of 05 mm Spiral Chute Successful Cases Korea 20TPH Tungsten Ore Processing Plant Mineral Processing Consulting Services Jig Concentrator JXSC Mineral2020年5月6日 — The Spiral concentrator has performed better at feed pulp density of 30% by producing concentrate of high grade (935%) and with highest recoveries of 96% The desliming of raw sand has been done using using hydrocyclone When the deslimed feed is fed to the spiral, high concentrate grades has been produced with very high recoveries Effect of Operating Parameters on the Performance of 2024年8月19日 — High efficiency silica sand classification spiral chute December13,2023 The spiral chute is a commonly used gravity mineral separation equipment, suitable for sorting iron ore, ilmenite, chromite, High efficiency silica sand classification spiral

Manganese Ore Process Plant JXSC Mineral

2024年9月29日 — Notes: The belt conveyor from jaw crusher to cone crusher will need to add the iron remover to make sure the safe and efficient work of the cone crusher The spiral chute will normally make two phases, the 2020年1月17日 — The spiral chute mainly uses the inertial centrifugal force generated by the mineral of different density in the rotating motion of the spiral to separate the heavy and heavy minerals At present, mineral resources are faced with such unfavorable conditions as depletion, refinement and hybridization, so improving the dressing efficiency of sorting How to Increase the Efficiency of Spiral Chute? Xinhai2024年9月29日 — A shaker table is also known as a gold shaking table, gold separation table, or concentrating table It is a fine gold recovery equipment common in the gold shaker wash plant, alluvial gold mining plant to separate concentrates, medium concentrates, and tailings according to material density and grain sizeShaker Table JXSC Mineral2019年8月26日 — Quartz processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Spiral Chute; Gold Mining Equipment; Mobile JigTrommel; JigRotary Scrubber; The highpurity quartz sand having a purity of 9999% can be obtained by the quartz Quartz Processing Equipment, Process Flow, Cases JXSC

.jpg)

How Rotary Spiral Chutes Optimize Mineral Recovery and Improve Efficiency

2023年8月7日 — Heavy mineral concentrate processing is a crucial step in mining operations, and the choice of equipment can significantly impact efficiency and recovery rates Rotary spiral chutes have emerged as a valuable tool for this task, offering several key advantages How Rotary Spiral Chutes Optimize Mineral Recovery Rotary spiral chutes excel in [Introduction]: Quartz sand purification is removal of a small amount of impurities and the high difficulty separation technique to obtain refined quartz sand or high purity quartz sandThe purification technologies of quartz sand at home and abroad are washing, classifying and desliming, scrubbing, magnetic separation, flotation, acid leaching, Quartz Mining, Mineral Quartz, Quartz Mining Process Xinhai2016年3月26日 — located at the bottom of the spiral (Photo 6) Spiral concentrators are used for the processing of heavy mineralbearing beach deposits in Florida and Australia The first commercially applied spirals were the cast iron Humphreys spirals introduced in the early 1940s These units were very heavy and difficult to adjust In addition,Gravity Spiral Concentrator Working Principle 911Metallurgist2023年8月3日 — 01 Silver ore flotation process Flotation is a method commonly used for silver extraction, especially for sulfide ores Specific process: The pulp after crushing and grinding is added to the flotation machineDuring flotation, appropriate flotation agents need to be added to the pulp to help the enrichment of silver ore4 Different Silver Extraction Process Methods Xinhai

Chrome Mineral Gravity Separation Technology,

2023年12月20日 — The above content is the gravity separation technology of chrome mineral, which can effectively separate chromite and gangue minerals to obtain highgrade chromite mineral concentrate This process 2022年7月15日 — The general leadzinc mineral beneficiation process is divided into four stages: crushing and screening stage —— grinding stage —— selection stage (flotation) —— concentration and dehydration What Is Spodumene Mineral Processing Flow?2015年12月1日 — BLL type glass steel spiral chute that Xinhai manufacturer is a kind of advanced placer gold ore dressing equipment In the working process, the slurry will be conveyed to the top of the feeding mouth by the pump, and add additional water to ensure the proper concentration of separation At first in the gravity effect, there will be mineral With Advanced Spiral Process, Do Good Job of Placer Gold 2022年9月28日 — This beneficiation process has the advantage of high beneficiation precision 2 Spiral chute tail throwingshaker beneficiation process If the production site of the concentrator is limited, the spiral chute tailingshaking process can be considered to Gravity and Magnetic Separation for Chromite Mineral Processing

Spiral Chute Spiral Separator Haiwang Technology Group

Haiwang Technology Group is the leading group that provides mineral processing, equipment manufacture and onestop service for mineral processing plant (EPC solution for mineral processing plant), which solve many problems for mine investors The LXA spiral chute independently developed and produced by Haiwang company independently The Tanzania 1,200t/d gold mineral processing plant was an EPCM+O project The ore consisted of sulfide (107g/t) and oxide (24g/t), with Au being the only valuable element They achieved a leaching rate of 9375% and 9158% respectively through the allslime cyanidation gold extraction processTanzania 1,200t/d Gold Mineral Processing Plant Xinhai2023年8月26日 — The beneficiation process involves several steps to remove impurities and obtain highpurity quartz sand: Mining and Crushing: Raw quartz ore is extracted from mines and undergoes coarse crushing to reduce particle size Grinding: The crushed quartz ore is further ground to achieve the desired particle sizeGrinding can be done using equipment Quartz Sand Beneficiation Methods Process JXSC Mineral2024年7月24日 — Company Introduction: Shicheng Oasis Mineral Equipment Manufacturing Co, Ltd is an importexport trade enterprise engaged in the production, sale and installation of mineral equipment, environmental protection equipment, hardware and machinery Our company has been approved for registration by relevant departments, and can provide High Performance Mineral Processing Separating Equipment

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and 2023年8月7日 — The process of spiral chute gravity separation is as follows: 1 Pretreatment: First crush and grind the ore into proper size 2 Feeding: Put the prepared ore evenly into the feeding port of the spiral chute 3 Movement: In the spiral chute, the ore slides down along the spiral chute wall Due to the helical design of the trough, the 4 Common Gravity Separation Methods Xinhai Xinhai 2024年6月7日 — The spiral chute plays an important role in the mineral mining and ore dressing industries as an efficient and practical gravity ore dressing equipment With Dasen Mining’s spiral chute equipment and Beyond Jigs: Advantages of Spiral Chutes in Fine 2020年11月13日 — While using the spiral chute to remove the heavy minerals in the quartz sand, it can also remove part of the flake mica minerals Equipment Needed: Spiral chute (4) Flotation Method If there Quartz Impurities Removal Process and

.jpg)

How to Increase the Efficiency of Spiral Chute?

2023年10月5日 — To increase the efficiency of a spiral chute, you can focus on several key aspects Here are five points to summarize the process: 1 Optimize Design and Geometry: — Ensure the spiral chute has 2021年3月8日 — IMPC 2020: XXX International Mineral Processing Congress, Cape Town, South Africa, 1822 October 2020 5 Separation efficiency on a spiral Yield, grade and recovery are the main separation attributes used to measure the performance of a spiral This paper uses the mentioned attributes in addition to the HollardBatt equation to calculateEvaluating separation efficiencies of Multotec’s new 2024年9月29日 — The output of the magnetic separator is sent to the spiral chute by a slurry pump Through gravity separation method to remove light minerals The spiral chute gravity separation plant has two stages: the middling from the first stage spiral chute plant goes to the second stage spiral chute for reprocessingRutile Processing Beneficiation JXSC MineralOur range of spiral concentrators Multotec Australia offers a wide range of spiral concentrators that can be found at our branches in Brisbane, Mackay, Perth, Newcastle, Newman and Emerald, Our range of spiral concentrators is designed for use in the mineral processing of chrome, coal, iron ore, gold, nickel and zinc The video below gives Spirals in Australia mineral processing Multotec

Gold Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月22日 — Gravity beneficiation is refers to separating gold ore according to mineral density and plays an important role in contemporary mineral processing methods The main gravity separator equipment are chute, shaker table, mineral jig, hydrocyclones, etc Gold flotation Flotation process is widely used for lode gold processing2024年9月29日 — Ilmenite gravity separation The gravity separation method is suitable for processing coarsegrained and finegrained aggregate disseminated ilmenite After crushing, the raw ilmenite ore is separated and discarded by gravity separation equipment, such as the shaking table, spiral chute, etcA large number of gangue minerals and slime are Ilmenite (Titanium) Mining Process JXSC Mineral2024年9月29日 — The working principle of the spiral chute is as follows: 1 The sand pump sends the ore to the two feed inlets at the upper end of the screw, adding supplemental water to adjust the concentration of the ore pulp; 2 The ore pulp naturally swirls from high to downward, generating a kind of inertial centrifugal force in the rotating slope; 3 As the Spiral Chute with High Quality Fote Machinery2024年9月29日 — The spiral separator is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table, and centrifugal concentrator Sprial Chute Working Principle Raise the spiral chute and fix it in the proper position, sand pump send the ore to the feed inlet, adding water to adjust Spiral Chute JXSC Mineral