Cone Mining Mill Pilot Plant Size

制粉项目-2023.11.17.jpg)

SAG Mill Testing Test Procedures to Characterize Ore

2022年6月29日 — The pilot plant can test coarse feeds (150mm), as well as essentially any test conditions, so it presents the lowest degree of scaleup within all the methodologies The mill is steel lined with a nominal 10 mm grate size with conventional hockey stick pulp lifters Outer discharge grate panels can be installed to facilitate two or four x 75 mm ports pebble portsSAG milling grinding pilot plants alsglobal2000年1月1日 — Abstract In the run of mine (“ROM”) autogenous and semiautogenous milling process, the influence of a single parameter cannot be determined easily as Runofmine milling pilot plant test work ScienceDirect2021年1月11日 — pilot plant tests on representative samples of minus six inch ore (F80), in order to understand design requirements It can now be shown that this method is costly Choosing a SAG Mill to Achieve Design Performance

An Integrated Mineral Processing Pilot Plant

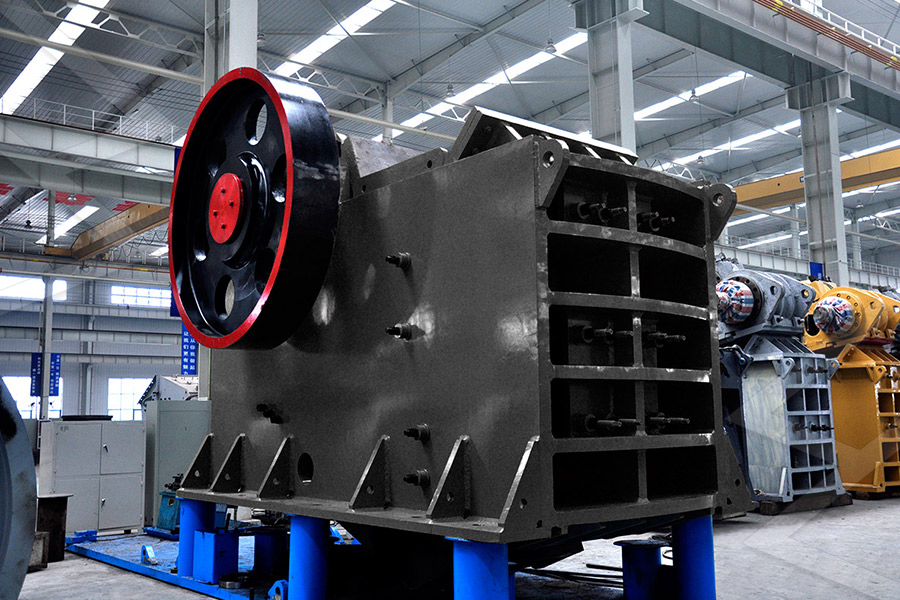

2007年1月1日 — The pilot plant units are configured to perform a similar duty (in terms of mineral content and particle size) to the fullscale operation and their response measured2023年10月20日 — In other words, the pilot plant with its digital twin may become the physical twin of the industrial plant as long as a robust scaleup methodology is available This Advanced Geometallurgical Characterization: Mini Pilot Plant It also has a larger input feed size up to 250 mm, with a 30 mm product size Powered for tough jobs Typical applications include primary crushing of large lump ore in sampling stations and pilot plants, the precrushing of Laboratory and pilot plant Primary Jaw CrushersFor over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and Crushers, Pulverizers, Grinders Lavallab

Cone Mill MKO Inline dispersers / Mills,

Pilot plants Inline dispersers / Mills Solidliquid mixers Kneading machines Batch dispersers Process plants Dry mills Vacuum dryers The IKA MKO 2000 is a highperformance inline cone mill capable of performing wet 2018年1月28日 — The pilot mine stage of a mining project may also be considered phase one production — or the first step on the path to fullscale production Unlike benchscale testing in the lab, a pilotscale mine The advantages of pilot mining in project 2022年6月29日 — with pilot plant confirmation sometimes required Table 2 – Approximate Range of Size Reduction in Comminution Tests, Devices and Processes Prim Crusher (Gyr/Jaw Roll Crusher Impact Crusher Tert Crusher (Cone) Sec Crusher (Cone) SMC Test® DWT AWI AMCT AG Mill Blasting CWI RWI Rod Mill Pilotscale HPGR SPT Lab SAG Mill Testing Test Procedures to Characterize Ore 2016年5月12日 — The chief advantages in using Portable Mills for pilot plant work in developing a large ore body are: First, the three persons most closely involved in developing the project successfully—the geologist, the mining engineer and the metallurgist— are able to work closely together in solving the problems of exploiting the ore body to greatest Small Mineral Processing Plant Design 911Metallurgist

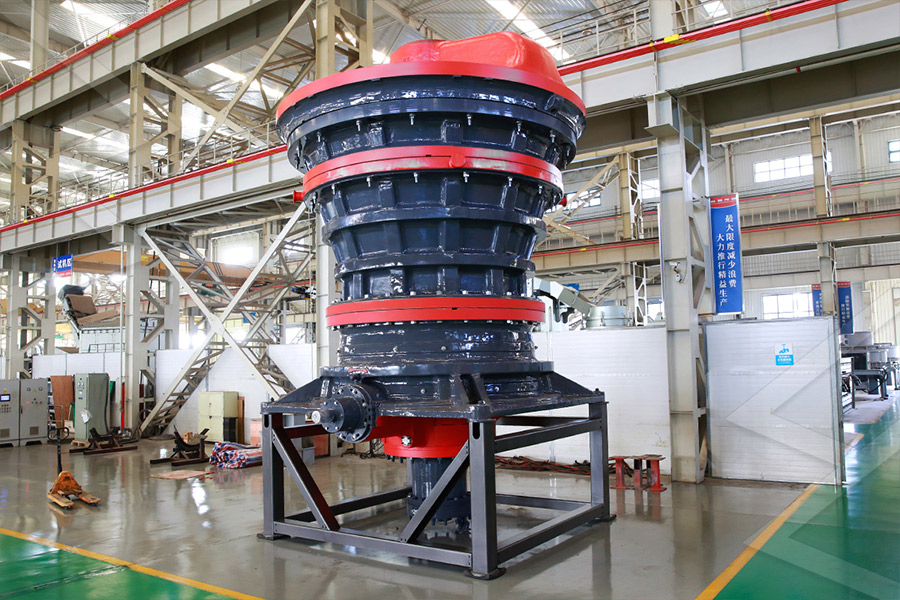

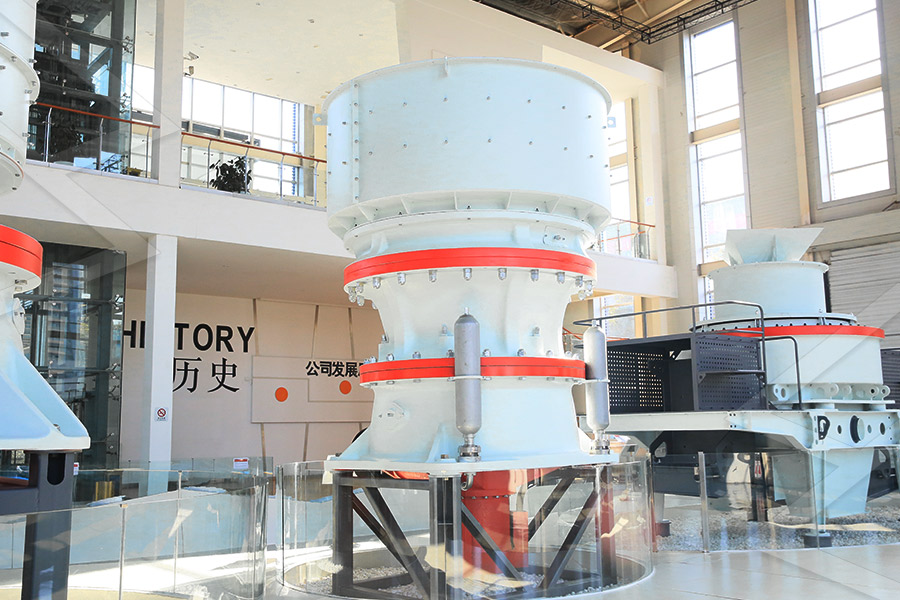

Cone crusher basics in 4 minutes SRP

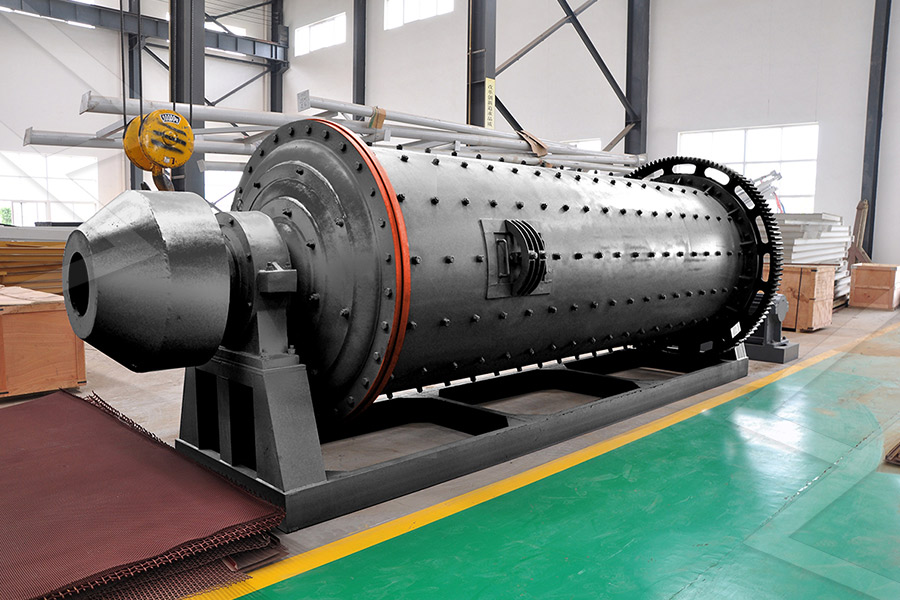

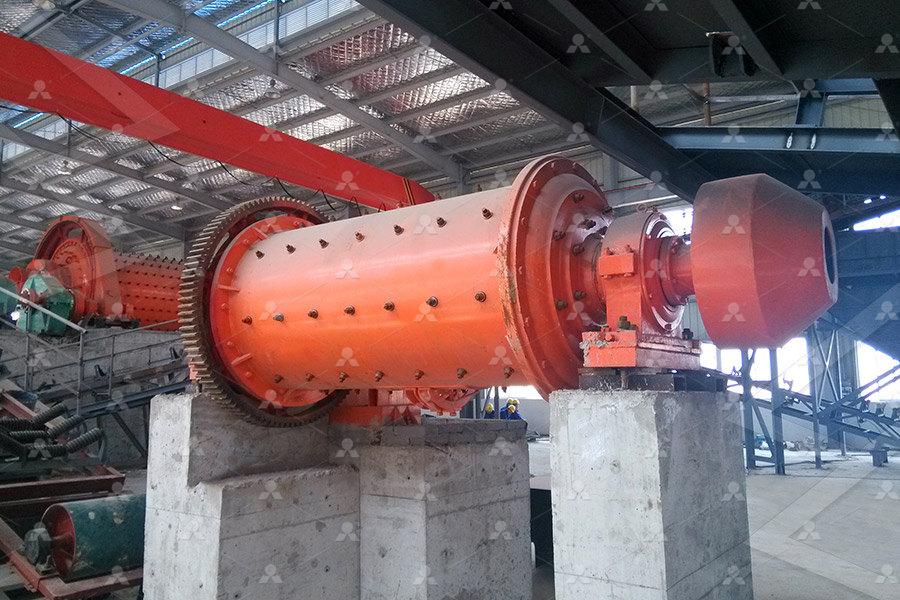

It’s hard to overstate the importance of feed size in a cone crusher It is vital that you know, as accurately as you can, the size distribution of the raw material It’s crucial that sampling is done regularly, especially when there are changes in blasting, mining or any other upstream processes Feed moving towards a crusher in the Cone Crushers; Laboratory Crushers; Classification Hydrocyclone Manufacturers; Grinding It is the perfect small grinding circuit for pilot plant operations or small micro mining Under specific conditions, it will grind finely crushed ( 6mm) ore to 75 microns Mill Shell size: mm: ɸ420×600: Mill speed: RPM: 53: Mill volume: L: 80 GRINDING MILL FOR METALLURGICAL PILOT TESTING OF 10 5 天之前 — XMQ Cone Ball Mill 【Capacity】:200 4000g/h 【Feed size】:≤3mm 【Processible Material】:gold, leadzinc, coltan, tantalite, iron ore, copper ore 【Application】: It is mainly suitable for crushing processing of various metal and nonmetallic ore raw materials test samples At the same time, it is used for ultrafine grinding Cone Ball Mill Super Fine Grinding Mill JXSC Machine2 天之前 — EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2120 TPH SELFSUFFICIENT MOBILE HARD ROCK GOLD MINING EQUIPMENT

A review of modeling and control strategies for cone crushers

2021年8月15日 — Bearman et al (1991) performed pilotplant scale experiments involving a laboratory scale cone crusher to understand and predict the following two operating characteristics: power consumption during the crushing stage; and product particle size distribution as a function of CSS, feed size and rock strength The authors drew some This 911MPEPF842 is a complete, but still small miniature froth flotation plant is ideal for inhouse pilot plant testing your mining projectIts layout is for a monometallic flowsheet (buy section for each additional metal)DELUXE FLOTATION PILOT PLANT2024年9月23日 — In June 2012, pilot tests were conducted on a 200 hp high speed cone crusher to determine the production and operating conditions over a wide spectrum of eccentric speed Every plant will have variations in the ore characteristics and feed rates throughout the life of the mine, and at times throughout a single shift of operation, which Pilot study on the influence of the eccentric speed on cone sag ball mill – Project Case – Cruher and grinder plant Ball mill A pilot plant scale SAG mill suitable for use in design of a commercial scale SAG mill The ball mill has a cylindrical outer chamber having flanges at opposed Pilot Plantscale Ball Mill Crusher Mills, Cone Crusher, Jaw

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 — Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titaniumThe modules Colloid Mill MK and Cone Mill MKO are used for wet or fine milling of hard and granular raw materials or for the production of finest emulsions as well as for improving of quality of finished dispersions The MK module consists of two cones with differently directed flow channels on their surfacesmagic LAB Pilot plants, IKA2021年8月1日 — Processing costs are predetermined prior to the mining operation using comparative studies with similar ore deposits, detailed laboratory tests and, if the project is profitable, testing in smallscale pilot plants with multiple processing options to better understand the optimal process flow for developing for the concentration plantCalculating ultimate pit limits and determining pushbacks in The 911MPEGM2024 is a mini but continuous grinding mill (8″ diameter X 9 5/8″ long) with an approximate capacity of 3 to 10 Kg/Hr (dependent on feed size and hardness) 75 mm diameter x 800 mm Long spiral classifier with tilt regulation from 16 to 22 degree; 200 mm Diameter X 240 mm Long Grinding Mill which can be used as Ball Mill or Rod MillSMALL GRINDING / REGRINDING MILL 3 TO 10 KILO/HR

Evaluating the performance of an industrialscale high

2023年1月1日 — In the metal mining industry, comminution regularly involves crushing and grinding and is widely acknowledged as the process consuming the most energy, accounting for up to 75 % of the energy consumed by a processing plant (Tromans, 2008)Crushing is shown to be more energyefficient than grinding in the comminution processing chain; Pilot MillPilot Mill Manufacturers, Suppliers and Exporters Application: cement plant;ball mill;mine Category: Minerals Metallurgy Cast Forged Labscale Pilot Jet Mill 100DSM for grinding and pulverizing dry, Pilot Scale Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers2015年8月7日 — The Volume of slurry that is being fed into the cyclone must not exceed the capacity of these two outlets that allow it to escape The size of the apex and the vortex finder is crucial If the apex of the cyclone, like the size of the drain in your sink, is made smaller it won’t allow as much slurry out of the underflow of the cycloneHydrocyclone Working Principle 911Metallurgist911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has Metallurgists Mineral Processing Engineers

cone crusher pilot plant size Sebocom Construction

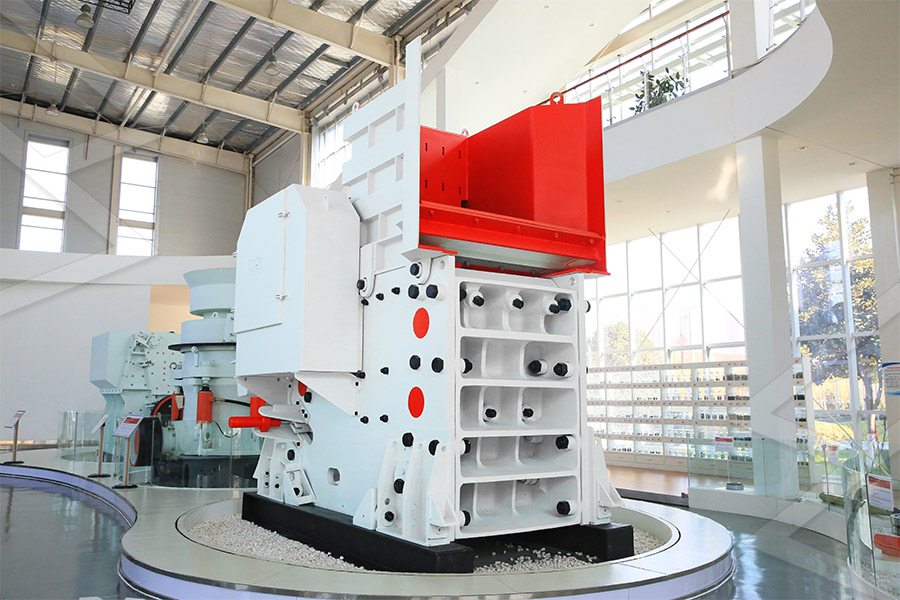

Cone Crusher Pilot Plant Size A cone crusher is generally used as a secondary crusher in a crushing circuit Precrushed product (usually 3in minus depending on the cone crusher model) is fed through the top of the cone crusher and flows over the mantle The vertical cone crusher drive shaft rotates the mantle eccentrically below the concave 2021年6月24日 — Published by Maney Publishing (c) IOM Communications Ltd and the Australasian Institute of Mining and Metallurgy Flotation data for the design of process plants Part 1 – testing and design procedures R C Dunne*1, G S Lane2, G D Richmond3 and J Dioses2 This paper discusses the methods used in the design of flotation plants, Flotation data for the design of process plants Part 12017年4月1日 — Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 2011 to 1140 kW h/t by using vertical roller mill instead of AG/SAG Operational parameters affecting the vertical roller mill 2016年6月6日 — To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be consideredSAG Mill Liner Design 911Metallurgist

.jpg)

MINI FLOTATION PILOT PLANT TESTING SGS

2024年3月27日 — a “mini flotation pilot plant” While the cost of sample acquisition from a resource for largescale pilot plants typically represents a large expenditure to our clients, the use of a mini flotation pilot plant provides you with the benefits of a largescale pilot plant at a fraction of the cost and time Requiring only a2023年5月11日 — Acidic precipitation Snow and rain with a low pH caused by industrial gases released into the atmosphere; Acidic rocks Igneous rock with a high proportion of silica; Acid mine drainage Acidic runoff water from mine waste dumps and mill tailings ponds; Adit A horizontal opening into the side of a mountain or hill for access to a 2024 Mining Terms Explained An Underground Miner2021年1月11日 — Figure 2: Pilot Plant kg/hr Vs Charge % by Volume This data is indicative of trends that were happening in the 3ft diameter SAG pilot mill They have not been proven in large commercial scale mills Because the grinding operation could be viewed through the open end of the SAG mill, it was evident that maximum throughput occurredChoosing a SAG Mill to Achieve Design Performance5 天之前 — Greensboro, NC The family history begins in 1846 when Herman Kahn left his home in Bavaria, Germany, for a new life with his sister’s family in the United States Nothing is reported until Herman Kahn (now changed to Cone) opened a wholesale grocery business, H Cone Sons, in Baltimore in 1870 His two oldest sons, Moses and Ceasar, Cone Mills Textiles History

Gold,Copper,Graphite,Quartz Processing Plant Design,

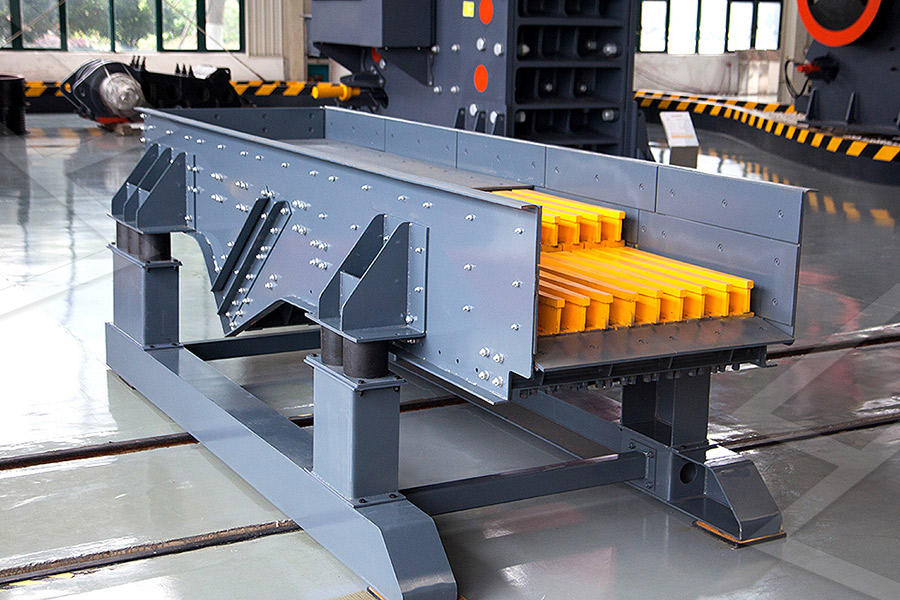

Ball mill and hydrocyclone system is the basic processing stage for different minerals like gold, iron, cooper, graphite, cobalt, etc Prominer maximum size of linear screen is 51m width and 85 m length and could customize the doublelayer banana screen with size up to width 49m and length 97m Spherical graphite pilot plant View 2017年2月13日 — experience or laboratory tests before mill size can be determined The required mill net power P kW ( = ton/hX kWh/ton) is obtained from P = const x c x q x nc x Li x Di25; where an approximate Ball Mills 911MetallurgistYou've already forked shibang 0 Code Issues Pull Requests Packages Projects Releases Wiki Activityshibang/sbm cone mining machine pilot plant sizemd at 2024年4月22日 — Furthermore, pilot plants enable the scaling up of laboratory results to a commercial production level, which can help to optimise the process and minimise risks before fullscale implementation Mineral Processing: Significance of Pilot Plants in

.jpg)

New, Used and Custom Mineral Processing Pilot Plants for

3 天之前 — We are a mining pilot plant equipment supplier worldwide We can provide custom built modular pilot processing plants specific to your application Our team can supply pilot plant design and fabrication services Custom built pilot plants can be mounted onto a skid and can often be loaded in shipping containersContribute to lbsid/en development by creating an account on GitHuben/165/ball mill lab pilot plantmd at main lbsid/en2021年3月5日 — The drilltomill methodology can be best defined as the development of integrated operating and control strategies from the mine to the plant that maximize throughput, minimize the overall cost per tonne, and maximize profitability The methodology involves a number of important steps: benchmarking (mine and plant), oreDRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS 2016年7月12日 — Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many Crushing Screening Plant 911Metallurgist

.jpg)

A Detailed Overview of Cone Crushers and What You Need

2020年6月3日 — In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be 2015年8月26日 — PILOT PLANT FLOTATION MACHINES of the DENVER “SUBA” Type Cells The No 5, No 7 and No 8 Denver “SubA” Flotation Machines are relatively small and designed for continuous service in laboratory, pilot plants and small scale commercial plants From mini to small scale flotation cells for piloting any mineral types, from copper Pilot Plant Flotation Cells Machines 911Metallurgist2012年8月7日 — Used Plant – Cone Crushers Gulin 4 1/4 Ft Standard cs series Cone Crusher Price: POA This is a UK manufactured » Free Online Chat Pilot Plants For Sale at Savona Equipment Ltd Your source for used pilot plants, used mining equipment, pipe, ball mills, rod mills, cone crushers, loaders, rock 50 Tons Per Day Pilot Plant Crushing price of pilot plant cone crusher – Grinding Mill ChinaFor over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and Crushers, Pulverizers, Grinders Lavallab

.jpg)

Cone Mill MKO Inline dispersers / Mills,

Pilot plants Inline dispersers / Mills Solidliquid mixers Kneading machines Batch dispersers Process plants Dry mills Vacuum dryers The IKA MKO 2000 is a highperformance inline cone mill capable of performing wet 2018年1月28日 — The pilot mine stage of a mining project may also be considered phase one production — or the first step on the path to fullscale production Unlike benchscale testing in the lab, a pilotscale mine The advantages of pilot mining in project 2022年6月29日 — with pilot plant confirmation sometimes required Table 2 – Approximate Range of Size Reduction in Comminution Tests, Devices and Processes Prim Crusher (Gyr/Jaw Roll Crusher Impact Crusher Tert Crusher (Cone) Sec Crusher (Cone) SMC Test® DWT AWI AMCT AG Mill Blasting CWI RWI Rod Mill Pilotscale HPGR SPT Lab SAG Mill Testing Test Procedures to Characterize Ore 2016年5月12日 — The chief advantages in using Portable Mills for pilot plant work in developing a large ore body are: First, the three persons most closely involved in developing the project successfully—the geologist, the mining engineer and the metallurgist— are able to work closely together in solving the problems of exploiting the ore body to greatest Small Mineral Processing Plant Design 911Metallurgist

Cone crusher basics in 4 minutes SRP

It’s hard to overstate the importance of feed size in a cone crusher It is vital that you know, as accurately as you can, the size distribution of the raw material It’s crucial that sampling is done regularly, especially when there are changes in blasting, mining or any other upstream processes Feed moving towards a crusher in the Cone Crushers; Laboratory Crushers; Classification Hydrocyclone Manufacturers; Grinding It is the perfect small grinding circuit for pilot plant operations or small micro mining Under specific conditions, it will grind finely crushed ( 6mm) ore to 75 microns Mill Shell size: mm: ɸ420×600: Mill speed: RPM: 53: Mill volume: L: 80 GRINDING MILL FOR METALLURGICAL PILOT TESTING OF 10 5 天之前 — XMQ Cone Ball Mill 【Capacity】:200 4000g/h 【Feed size】:≤3mm 【Processible Material】:gold, leadzinc, coltan, tantalite, iron ore, copper ore 【Application】: It is mainly suitable for crushing processing of various metal and nonmetallic ore raw materials test samples At the same time, it is used for ultrafine grinding Cone Ball Mill Super Fine Grinding Mill JXSC Machine2 天之前 — EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2120 TPH SELFSUFFICIENT MOBILE HARD ROCK GOLD MINING EQUIPMENT

.jpg)

A review of modeling and control strategies for cone crushers

2021年8月15日 — Bearman et al (1991) performed pilotplant scale experiments involving a laboratory scale cone crusher to understand and predict the following two operating characteristics: power consumption during the crushing stage; and product particle size distribution as a function of CSS, feed size and rock strength The authors drew some